- English

- 简体中文

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

Post legere hoc articulum, quod est facile eligere auto-lubricating gerunt, repugnans materiae!

2025-06-12

Quid opus auto-lubricating plastics?

Friction et gerunt mechanica components semper fuit clavis provocatione - traditional frictio reductionem modos qui confidunt in externa lubricants non solum inhaerens defectus, ut oleum adsorature in extrema operating in tempore stabilitatem requisitis in extremum operating conditionibus. De nativitate auto-lubricating plastic materiae est a novis solution ad hoc dolorem punctum. Per aedificatum, in solidum Lubricant ut PTTFE, Graphite, Molybdenum disulfide vel M. structuram consilio, hoc genus materia est praeditus cum "auto-lubricatae gene", quod potest effectum absque externa lubricatae;

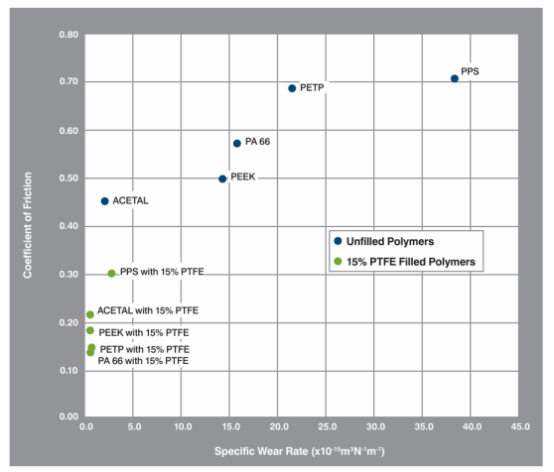

✅ Ultra-humilis coefficiente friction (0.050.2, proxima ad glacies illapsum characteristics)

✅ Super gerunt resistentia (XXXV temporibus iam vita quam metallum gestus)

✅ significant tremens et strepitus reductionem (sonitus reductionem MXX Decibels)

✅ sustentationem libero (praesertim idoneam extrema environments ut altum et humilis temperaturis, vacuo, etc)

Discover: De Scientia de auto-lubricating perficientur

Et egregie perficientur de auto-lubricating plastics est effectus ex Interdisciplinary Innovation in Materials Scientia et Tribology:

I. Duplici praesidio mechanism ad friction et gerunt

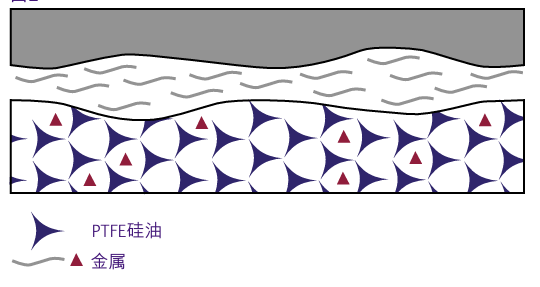

Sapientis labore Imperium, cum materia movet ad metallum superficiem, in aedificatum in lubricant forms a Nano-scale "transferre amet" in contactu interface, agens in invisibili "ad contactus scutum" ut isolate Direct Frict.

Abrasive gerunt resistentia: summus vires firmfroging augmenta ut ipsum fibra et speculum fibra sunt sicut "corpus armis" intra materiam, effective vel calculo exesa.

Analysis of Key euismod parametri:

Gerunt coefficientem K:

◦ Core Laboratory Metrics: A 0,1 × 10⁻⁻⁰ minor in K valorem est consociata cum 1.5-complicare incremento in component vitae

◦ ipsam Certamina Formula: Gere Volume = K × pressura × celeritate × tempus (E.G., Pa66 XXX% speculum fibra nobis Uhmwpe, K valorem, 0.05, in vita, in vita, in eadem 0.05 in vita, in vita est in eodem tempore 0.05, in vita est in eodem modo in vita 0.05, in vita est in vita, in eodem modo 0.05 est in vita, in vita, in eadem vita est 0.05, in vita, in vita est in eodem modo 0.05, in vita est in vita, in eodem modo 0.05 est in vita, quam 0.05 est in vita, in vita, in eodem modo in vita 0.05, in vita est in vita, in vita est, in vita est, in vita, in eodem modo 0.05 est in vita, in eadem vita est, in vita, in vita, in eadem vita est 0.05, in vita, in vita est in eadem vita est 0.05, in vita, in vita, quam 0.05

PV terminus values: et "laquearia" de materia scriptor onus-afferentem capacitatem

Euismod rex: Peek Carbon Fiber (XIII MPa · M / S, comparari ad aerospace ferre ferrum)

Optimus Price / Effectus Ratio: PL66 PTFE (3.3 MPA · M / S, tantum 1/3 de sumptus of metallum)

Environment Expertus: Pi (1.8 MPa · M / S, CCC ° C High Temperature firmum operationem)

II. Synergistic mechanism of lubricants

PTFFe (PolytemTrafluoroethylene) 0.1 micron particulas partum a "Molecular-scale skating layer" in superficies cum coefficiens frictioni quod humilis ut 0.05.

Molybdenum disulfide (Mos₂) stabilis lubricatae perficientur in summus temperatus environments, praesertim idoneam ad altus-onus missionibus ut automobile engines.

Silicone oleum ptfe compositum ratio: Silicone oleum cito migrat ad superficiem ad formare lubricating film, quod valde brevis est currere-in tempore apparatu et realizes "lubricatae in satus-sursum."

Multi-dimensional perficientur securitate ratio

Et firmum perficientur de auto-lubricating plastics pendeat in praecisam coordinationem materiae formula, coronam processus, et structural consilio, a Molecular torquem orientation potestate ad auctum tempus dispersione technology, omnis link habet subruit tribological simulation et duram operantes condicionem temptationis.

Cross-domain applicationem territorio

I. Industrial Locus innovation

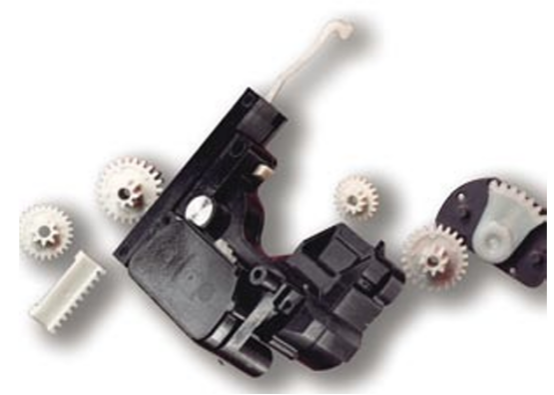

Mechanica Engineering: Silens gestus ad textile machinery et sustentationem-liberum Gears in aqua metris, in ministerium vitae augetur plus V temporibus

Books Industry: Gasket quod operatur stabiliter in CXX ° C oleum environment totaliter excludit abnormes sonitus ostium cras

II. Maximum-finem vestibulum breakthroughs

Aerospace: De Hinge de Satellite solaris panel factum est de Peek Ptfe Material, quod maintains aequaliter gyrationis sub extrema temperatus difference of CLXXX ° C CCLX ° C (Peek-fundatur ad CCLX potest resistere maximum ° C CCLX

Biomedical: Uhmwpe artificialis iuncturam materiam, friction coefficientem sicut humilis ut 0,02, orci ministerium vitae magis quam XX annorum

Directionem futurum technology evolutione

Cum ad iteration of material modificatio technology, novum generationem auto-lubricating plastics est provocans ad extremum scene:

Ultra-High Temperature Lubrication: Polybenzimidazole (PBI) Material erumpit per temperatus resistentia terminum de CD ° C et AIMS ad Core components of Aero Engines

Space-gradu praesidio: Graphene, adiutrices Composite resistite Mundi Radiorum et Micrometeorites

Biodegradable lubricatae: biodegradable materia ad implantabilia medicinae cogitationes, plene bioabsorbable post surgery

Et emergentielii de auto-lubricating plastic materiae non solum redefines ad tributalia proprietatibus mechanica partibus, sed etiam aperit in novam iter in agro viridis vestibulum et intelligens sustentationem. From industrial production lines to aerospace equipment, from vehicles to human organs, this "invisible technology" that integrates material science and engineering wisdom is quietly promoting the global manufacturing industry to be more efficient, intelligent and sustainable with the characteristics of low energy consumption, long life and maintenance-free. In futuro, cum breakthroughs in secans-ore agri ut nano lubricyrictione et auto-sanitatem materiae, mechanica systems ut in aliter 'nulla frictio "era.