- English

- 简体中文

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

Adhuc luctantem plastic calor dissipatio? Hic 'a comprehensive acquisitionem dux pro thermally PROLIXUS plastics!

2025-04-15

I. Key Characteres de Thermally PROMMOGTIVUS plastics

I. Effectus commoda

Weight Commodum Collegit: cum densitas tantum duas ex tribus, quod Aluminium Alloys, qui significantly augendae productum Lightweighting.

CUMATIUM Efficens: utilitas iniectio CUMATIUM processibus, eliminating post-processus gradus in traditional metallum machining et brevientes productio cycles.

Cost-efficaciam: superior pretium-perficientur ratione debitum ad dispensando efficientiam, materiam pondus reductionem et Eco-amicitia.

Aliquam Benefits: Cleaner Production Processus, RecyClability, et inferior Carbon vestigia comparari metallis et LATERAMEN.

Design flexibilitate: enable universa geometries et tenuis-muratas structurae diverse applications.

Electrical Safety: miscere scelerisque conductivity cum optimum velit, idealis pro non-solitaria potentia commeatibus.

Chemical stabilitatem: outstanding corrosio resistentia diu terminus usum in dura environments.

II. Euismod collatio

II. Scelerisque doctrina et calor dissipatio consilium

I. æstus translatio machinationes

I. Convenienti:

- Sust newton 's refrigerationem legem, fretus in fluidi (E.G., Aeris) motus. Coactus convection (E.G., fans) Enhances calor commutationem.

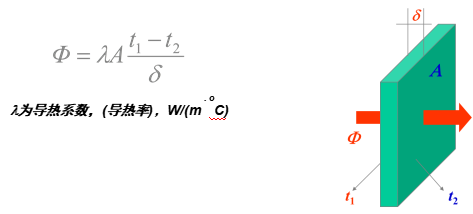

II. Conduction:

- Efficientiam positum est:

- Efficens Contact Area

- materia crassitudine

- Poeming conductivity (λ)

(Metallis traditionally dominari hic)

III. Radialis:

- infrared radiation (8-14 μm unam) transfert industria, afficit:

- Calor geometria descendat

- effective radiation superficies regio

- Material Emissivity

II. Thermal resistentia Model

Totalis ratio scelerisque resistentia (RJ1-RJ5) est series sum. Thermally PROLIXUS plastics optimize Duo discrimine resistunt:

RJ3 (substrati materia resistentia)

RJ5 (calor submersa-aere interface resistentia)

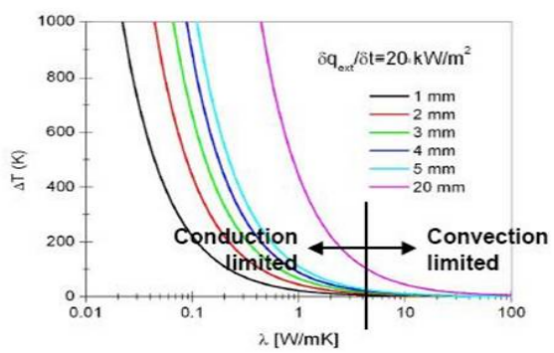

III. Critica scelerisque conductivity limina

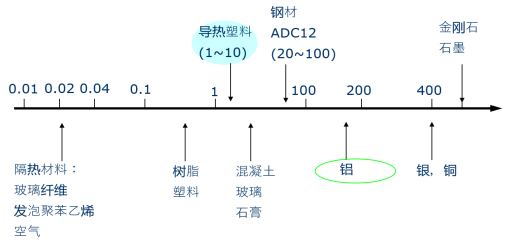

Cum λ> V w / m K et crassitudine IV. Plastic vs. Metal scelerisque conductivity Traditional View: Metals (E.G., Aluminium, Λ≈200 W / M · K) domini DUXERIT FORMIDUS MULINUS, dum Plastics (λ

Key Inventiones: I. Minimum λ ( II. Breakthrough range (Λ≥5 w / m · k + crassitudine III. Substitution Fasibility: Plastics cum Λ≥20 W / m K (1/10 metallis) et Innovation: Thermally PROLIXUS Plastics (Λ≥5 W / M K + Wall Wall Design) Disrupere metallum, dependens paradigms. III. Material compositionem et lectio I. scelerisque fillers Metallicis: Electron-repulsi (E.G., Cu / al pulveris) - agentibus et PROLIXUS. Non-metallicum: Phonon-repulsi (E.G., Alico₃, BN) - Electrically insulating. II. Filler perficientur collatio III. Matrix et formula Polymers: PPS, PA6 / LXVI, LCP, PC - Libra temperatus resistentia, processability et sumptus. Euismod types: Insulating: Oxide / Nitride Fillers (E.G., Alico₃ + P6). PROLIXUS: Metal / Graphite Fillers (E.G., Carbon PA +). IV. Market Overview et Products

I. Global faces SABIC: DTK22, Ox11315, OX10324, PX11311U, PX11313, PX13322, PX13012, PX10323 Envalior: D5506, D3612, STANYL-TC154 / CLV, TKX10110D, D8102, STANYL-TC153 Celanese: D5120 II. Material Electio Criteria Thermal euismod: summus Λ fillers (BN / sic enim postulans applications). Electrical Safety: Insulating Fillers (Alico₃ / BN). Moldability: High-fluxus Polymers (E.G .: Nylon) ad universa partes. Custus: Alico₃ est cost-effective; BN Premium. III. Industry innovations R & D: High-Filler, humilis-viscosity compositis (Nanofiller technology). Euismod Breakthroughs: Insulating Plastics Achieving λ> V Latin / M K · K. IV. Market Outlook 5G, EVS et Mini duxit adoption, demanda crescit ad lightweight scelerisque solutions (E.G., automotive electronics, wearables).